1. Working Principle of Labeling Machine The labeling machine adopts high precision intelligent electric eye combined with extremely reliable PLC controlling to divide labels into lots and labeling. By adsorbing adhesive stickers into the labeling head with air pressure, the labeling can be realized.

2. Advantages of Labeling Machine

a. Labeling speed is up to 60 times/minute.

b. Labeling bottle size is adjustable to meet the different labeling needs.

c. Excellent effect can be delivered for labels with no wrinkles and no bubbles.

d. Could be working independently or coupled with production line.

e. Choosing brand PLC and sensor etc electronic components which working stably.

f. Modular design, convenient maintenance and low repair cost..

3. Applicant of Labeling Machine

a. Different kinds of objects' flat labeling, widely applied in cosmetics, daily chemical, electronics, food and medicine.

b. Flat labeling on the surface of square bottles for cosmetics, medicine.

c. Flat labeling or anti-counterfeit labeling on the surface of various kinds of boxes.

d. Flat labeling on LCD screen, electronic components.

|

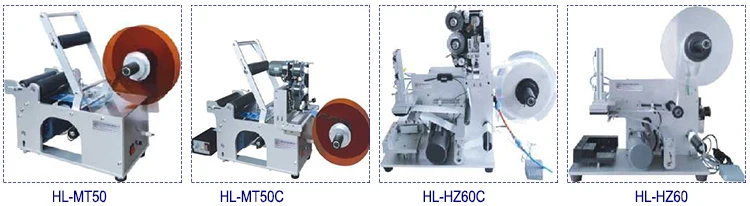

Name

|

Plane labeling machine

|

|||

|

Model

|

HL-HZ60C

|

|||

|

Voltage

|

220V 50HZ /110V 60HZ

|

|||

|

Power

|

120W

|

120W

|

220W

|

120W

|

|

Label speed

|

25-50 pcs/min

|

|||

|

label accuracy

|

±0.5mm

|

±0.5mm

|

±0.5mm

|

±1mm

|

|

label roll inner diameter

|

≥75

|

|||

|

max label roll out diameter

|

≤Ø250mm

|

|||

|

products size

|

Ø20mm-120mm

|

10MM-120MM

|

||

|

wide of label

|

W150*L230

|

W150*L230

|

W150*L230

|

10MM-120MM

|

|

printer

|

NO

|

NO

|

YES

|

NO

|

|

Machine size

|

65*45*45CM

|

65*50*45CM

|

65*45*65CM

|

65*45*70CM

|

|

Gross Weight

|

25KG

|

35KG

|

35KG

|

26KG

|